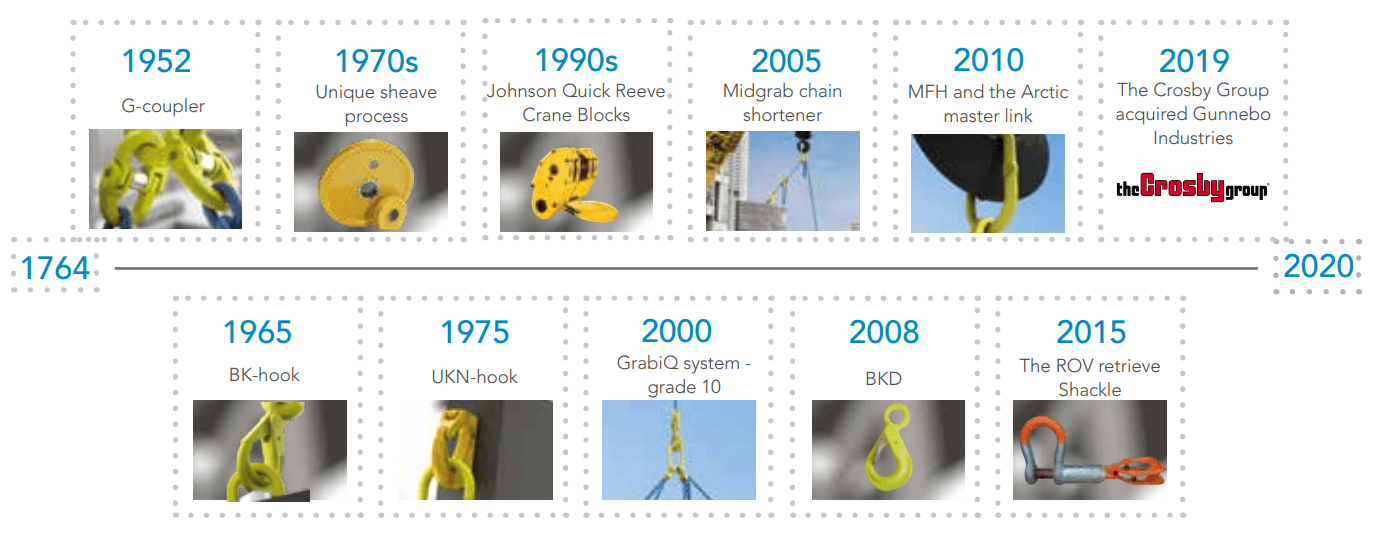

A legacy of innovation

In 1764 Hans Hultman founded Gunnebo Industries in the shape of a hammer-smithy in Småland, Sweden.

Gunnebo Industries was acquired by The Crosby Group in 2019, and as a group we continuously drive innovation through product development to create the optimal solutions for each lifting situation. Since the early 1950’s we have developed products that are today’s standards on the market and copied by almost all manufacturers of lifting equipment.

Wide range of products and applications

Chain & Lifting Components

Our chain and components are made from special hardened and tempered alloy steel that guarantees high strength, low weight, high wear resistance and long life. All components are uniformly marked with chain size, grade, manufacture’s designation and name. Every forged component is tested to the Manufacturing Proof Force before leaving our factories in Sweden.

The GrabiQ System

Our GrabiQ Grade 10 range features integral shortening, reduced number of components and more flexible use of chain slings. This provides a modular concept for cost effective lifting solutions that covers a wide set of applications.

Lifting Points

Our wide range of lifting points allow us to provide complete solutions developed for each customer’s needs, enabling improved operational efficiency for our customers. All of our Lifting Points are CE marked. Each lifting point has been proof loaded to 2.5 times the Working Load Limit and visually inspected by a licensed inspector before leaving the factory.

Shackles & Rigging Screws

Our shackles are available in a broad range of steel including acid proof stainless steel and high grade alloy steel to comply with the most stringent specifications. Several of our shackles are also Type Approved to DNV 2.7-1.The production of shackles and rigging screws takes place in our factory located outside Bergen, Norway.

Aquaculture

Our maritime products are made for a life under water. For example, our Hot Dip Galvanized (HDG) lifting range is designed to meet the specific challenges from corrosive environments in which they will have a longer lifetime. In the long run our HDG products require less maintenance and are more cost effective.

Arctic Offshore

Adverse weather and rough sea conditions, sometimes in combination with extremely low temperatures, must be considered in the design of offshore lifting sets. Our offshore range is produced from steel that gives improved impact strength at low operating temperatures, as well as reduced risk for hydrogen embrittlement.